12 Station Rollform, Profile Production Line, ECO (Start-Stop)(40m/min)

(Eco R-030-080)

12 Station Rollform

ECO Profile Production Line

PROMOTIONAL

Safe Work, Safe Workmanship

Service Services

Eco-Friendly

+A Electricity

Touch Screen

APPLICATION

12 ST

Station

5.5 kW

Motor

Alpha Machinery Drywall Profile Production Line

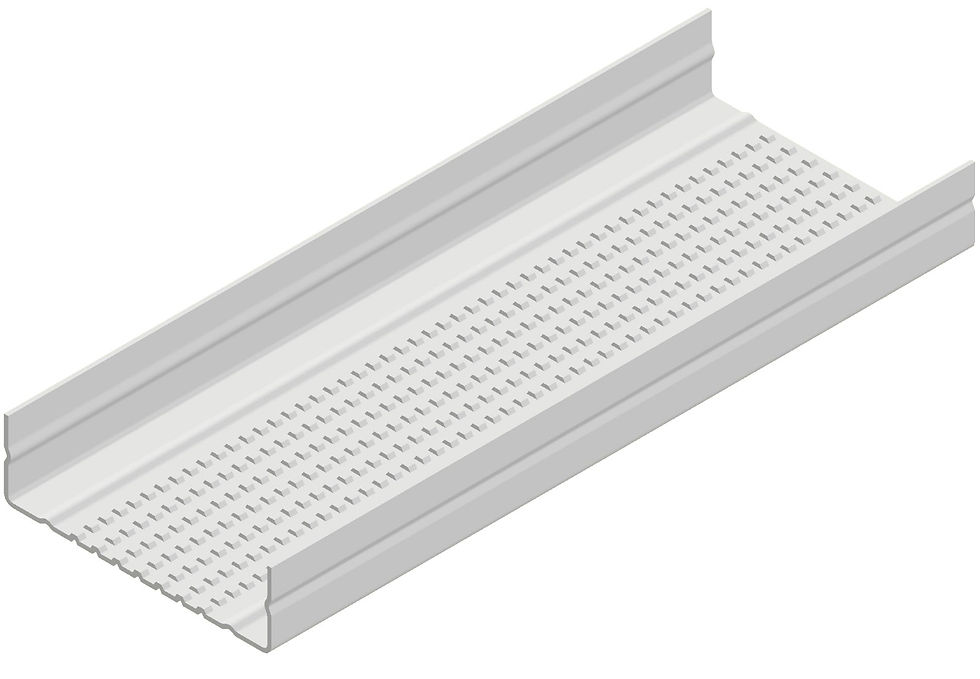

The 12-station rollform line operates at a maximum speed of 40 meters per minute, shaping sheet metal plates ranging from 0.30mm to 0.80mm. Based on customer demands, once the design and production of the roller and cutting set suitable for the desired profile types are completed, the production of the desired profile can be carried out on the line. The rollform line stops when the profile reaches the desired length to perform marking, hole punching, and length cutting, operating on a start-stop basis. Therefore, it operates at a lower speed compared to our RF030-080-100 model with a servo flying shear, making it a more economical model.

In our standard machines, variations in rollform line elements can be applied according to customer demands and profile types. (The decoiler clamping action can be manual or hydraulic. The number of stations can be increased or decreased according to the profile shape and size. Different designs can be applied according to the shape and number of marks and holes on the profile. The stacking table can also be modified to be semi-automatic or fully automatic depending on the length and shape of the profile to be produced

12 Station Rollform, Profile Production Line, ECO (Start-Stop)(40m/min)

(Eco R-030-080)

TECHNICIAL

12 Station Rollform Line

-

12-station roll-forming roller station

-

5.5 kW Motor

-

Adjustable pressure roller axis

-

Sheet metal positioning with bearings

-

Hydraulic cutting unit

Feeding Tunnel

Safety fence guard

Decoiler

-

Maximum weight capacity of 2.5 tons

-

Maximum coil outer diameter capacity of 1600 mm

-

Minimum coil inner diameter capacity of 508 mm

-

Maximum sheet width of 350 mm

-

Motorized speed control

-

Safety cover for worker and job security

Stacking Table

-

Profile stacking and storage

Machine Outputs

Machine Technical Specifications

-

Total Power: 18 kW

-

Voltage: 380 Volt (AC)

-

Frequency: 50 Hz / 60 Hz

-

Power Supply: 400V 3F+N+PE

-

Air Pressure: 6 psi

-

Control Panel and Automation: Delta & GMT

-

Motor Supplier: Yılmaz Motor ve Redüktör

-

Mold Material: Ç4140/2379

-

Hydraulic System: Galtec from Italy

-

Pneumatic System: Fusco

TECHNICIAL SPECIFICATIONS

Decoiler

-

Maximum weight capacity of 2.5 tons

-

Maximum coil outer diameter capacity of 1600 mm

-

Minimum coil inner diameter capacity of 508 mm

-

Maximum sheet width of 350 mm

-

Motorized speed control

-

Safety cover for worker and job security

Feeding Tunnel

-

Safety fence guard

12 Station Rollform Line

-

12 station rollform roller station

-

5.5 kW Motor

-

Adjustable roller axis

-

Bearing sheet entry positioning

-

Hydraulic length cutting unit

Stacking Table

-

Profile stacking and storage